Oxidation & Corrosion

Copper Strip Corrosion

The Copper Strip Tarnish Test assesses the relative degree of corrosivity of petroleum products, including aviation fuels, automotive gasoline, natural gasoline, solvents, kerosene, diesel fuel, distillate fuel oil, lubricating oil and other products. A polished copper strip is immersed in 30 mL of sample at elevated temperature. After the test period, the strip is examined for evidence of corrosion and a classification number from 1-4 is assigned based on a comparison with the ASTM Copper Strip Corrosion Standards. For aviation fuels and natural gasoline, the sample tube is placed inside a stainless steel bomb during testing.

Test Bomb Baths

Thermostatically controlled water bath immerses Copper Strip Corrosion Test Bombs at the required depth per ASTM specifications. Use for testing aviation gasoline, aviation turbine fuel and natural gasoline. Fully insulated, double-wall stainless steel construction. Choice of four-bomb and eight-bomb models. Optional removable test tube rack converts four-bomb model for testing of products not requiring corrosion bomb.

Test Tube Baths

Constant temperature bath immerses 20 test tubes for copper strip tarnish tests of products not requiring a test bomb, including: diesel fuel, fuel oil, automotive gasoline, Stoddard solvent, kerosene and lubricating oil. Operator and equipment are protected by an overtemperature control circuit which automatically interrupts power to the unit should bath temperature exceed a programmed cut-off point. Welded stainless steel inner wall and powder coated steel outer wall construction with built-in support rack. Fully insulated.

Oxidation Stability Liquid and Solid Baths

Provides an indication of the tendency of gasoline and aviation fuels to form gum in storage. The sample is oxidized inside a stainless steel pressure vessel initially charged with oxygen at 100psi (689kPa) and heated in a boiling water bath. The amount of time required for a specified drop in pressure (gasoline) or the amount of gum and precipitate formed after a specific aging period (aviation fuels) is determined.

-

Conforms to ASTM D525, D873, ISO 7536 and related specifications

-

Oxidata® Pressure Measurement System

-

Available in two, four or six-unit configurations

-

Choice of water/liquid or solid block heating baths

-

Oxidation pressure vessel incorporates burst disk assembly

Corrosive and Oxidation Stability of Hydraulic Oils, Aircraft Turbine Engine Lubricants, and Other Highly Refined Oils

Evaluates the ability of a lubricant to resist oxidation and the formation of corrosive acid compounds by subjecting a sample to accelerated oxidation conditions in a catalytic environment. The sample is maintained at elevated temperature and subjected to a controlled air flow while in the presence of a series of test specimens made of metals commonly found in actual service conditions.

-

Models for ASTM, Federal and IHC test methods

-

Six-sample testing capability

-

Solid aluminum block design

-

Microprocessor temperature control with digital display and overtemperature protection

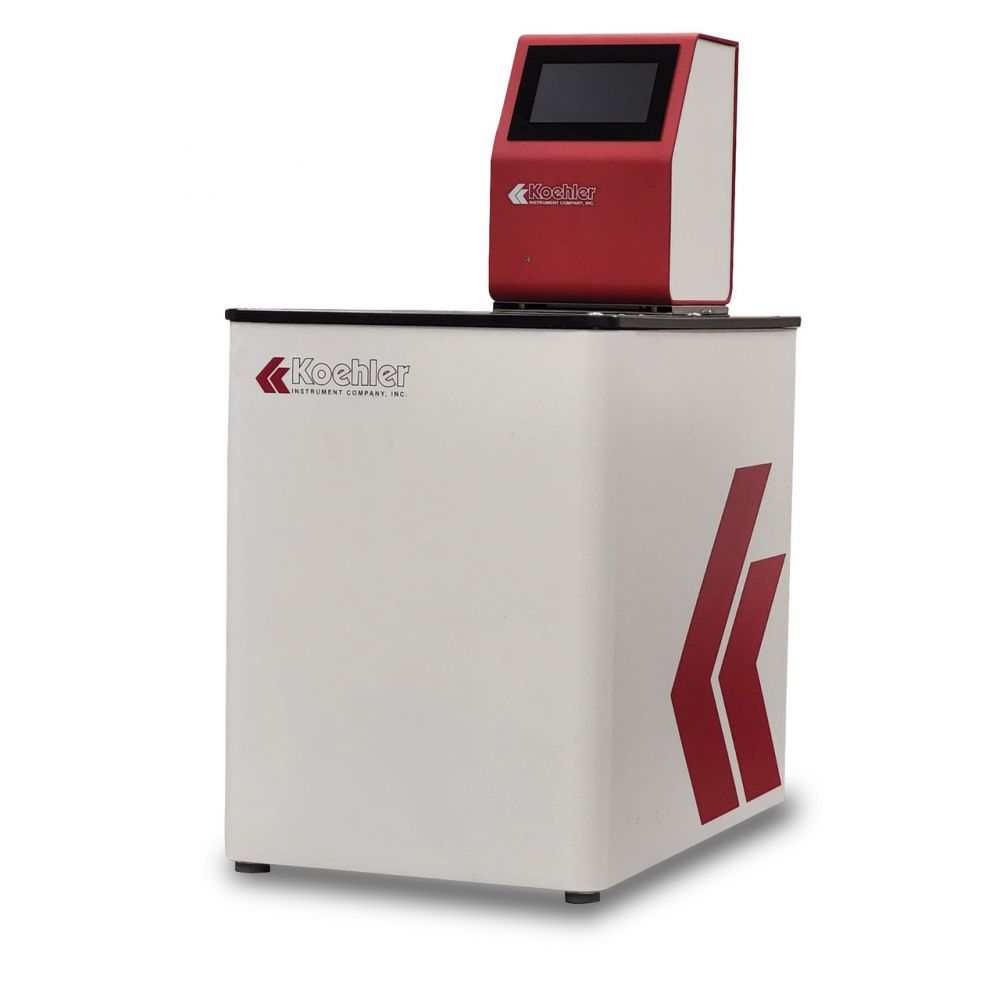

High Temp Convertible Oxidation Bath

Various methods are available for testing the resistance to oxidation and/or the corrosiveness of lubricants, insulating oils, hydraulic oils and distillate fuel oils. The samples are subjected to a metered flow of air at elevated temperatures, sometimes in the presence of a metal catalyst.

-

Conforms to various ASTM, Federal and International Standards

-

Removable racks hold different types of glassware for different tests

-

Equipped with flowmeters or digital mass flow controls to measure and control the required flow rates

-

Microprocessor digital temperature control

NACE Rust Preventing Characteristics Oil Bath

Used to control corrosion in product pipelines caused by moisture condensed from gasoline and distillate fuels. Antirust properties are determined by immersing a polished steel test specimen in a stirred mixture of the sample and distilled water held at constant temperature.

-

Conforms to NACE TM-01-72, ASTM D665* and D3603* specifications

-

Accommodates six sample beakers

-

Microprocessor temperature control with digital display

For Product and Sales Information Contact Us Today

sales@choiceanalytical.com or 832-271-7448